Auto Crane leads the market with unmatched technological advancements

Famous for inventing the very first mobile field service crane, Auto Crane has several cutting-edge innovations in the market today, with more advancements to come. A wholly owned subsidiary of Ramsey Industries, the fast-growing company engineers, designs and manufactures a comprehensive line of electric and hydraulic service cranes, work truck bodies, advanced crane control systems and accessories. For more than six decades, its industry-leading products have been trusted and used to support key industries and infrastructure projects. Professionals working in diverse fields such as heavy construction, energy, marine, mining, railroad, forestry and agriculture all rely on Auto Crane products to do much of their heavy lifting every day.

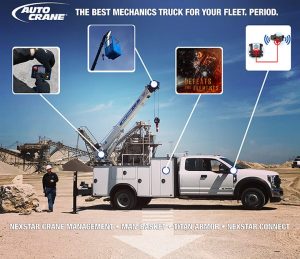

Among Auto Crane’s latest advances are the popular HC-7x and HC-8x NexStar 4 hydraulic service cranes. With lifting capacities between 3,000 and 8,000 pounds depending on model, and a reach of up to 30 feet, these cranes boast the longest reach for a service crane mounted on Class 5 chassis.

Auto Crane’s 8,000-pound lift capacity crane offers one of the lightest 30-foot service cranes in the market. Utilizing a large crane on a smaller service truck while preserving payload capacity for mechanic’s tools has been well-received by the market and applauded by end-users as key tool helping technicians get work done faster and safer without the need for larger, more expensive chassis.

Auto Crane is known as an industry pioneer in service crane innovations. It introduced the first electric cable crane with new and unprecedented lifting capacities for big equipment and the first electric-hydraulic service crane. It also introduced the first fully hydraulic line of service cranes to the market, which improved worker productivity with fully hydraulic hoists, boom extensions and power rotation that could operate for much longer service intervals than electric cranes.

“On the product side, we continue to break new ground annually,” says Scott Hausman, Director of Sales and Marketing at Auto Crane. “Much of our direction for innovation comes from listening to end users and our dealer network, something Auto Crane takes great pride in. Our products offer time-tested reliability, made in the USA quality, and are backed by the best warranty in the business.”

Innovative Technology

Innovative Technology

Auto Crane’s patented NexStar® crane management system is another industry first. It delivers full power and total proportional control on hydraulic cranes, allowing precision load handling with remote-controlled ease. “It takes care of all the safety aspects of operating the crane,” Hausman says. An optional feature, NexStar was first introduced to the industry about 15 years ago. In 2021, the company rolled out its newest version: NexStar 4. “The design of the handheld remote is improved to take even more abuse in the field,” states Mike Heffron, Southeast Region Sales Manager for Auto Crane. “It is a tremendous advancement in the way the remote assists operators with easy handling of the crane. For hydraulic cranes, NexStar allows 100 percent independent proportionality in all functions simultaneously, and similar performance in electric over hydraulic cranes. The level of control that you can achieve with NexStar 4 is unparalleled.” In addition, the rugged multi-function remote control transmitter is 70 percent lighter than similar pistol grip handhelds. The receiver’s LCD screen clearly displays more crane and load information in readable English — no codes to memorize or look up. At the heart of the fully proportional control is the exclusive Hydraulic Valve Bank, which delivers 100 percent hydraulic flow power for every crane function on command, every time. No split flow means no slowing down performance when an operator adds a function.

Sustainability and Engine Idle mitigation

Auto Crane is also leading the service crane market with the addition of Titan Connect® and Power on Demand ® to its innovation portfolio. “We were the first company to integrate our crane with other truck accessories, and now we are making it so much easier to offer sustainable solutions for crane and compressor operation by automating the engine starting and stopping to maximize fuel savings,” says Hausman. “Titan Connect is an advanced, solid state wiring system with an integrated Power Distribution Module. Power on Demand utilizes proprietary software to communicate directly with the truck to start, ramp up to high idle, and shut down when auxiliary power is no longer needed.” This technology helps maximize productivity and provides for telematics integration. It monitors equipment to help increase safety and allows operators to see equipment status in real-time and view historical data to help fleet managers optimize their equipment on future builds. “The information that it captures is invaluable to a fleet manager,” Hausman says. “It adds a layer of safety and accountability. If a mechanic uses their crane inappropriately, Titan Connect captures that data and makes that information available to the Fleet Manager so they can mentor the operator for their own safety. It is gaining a lot of interest especially from data driven companies,” Hausman says. “No one has publicly launched anything similar in this segment of the industry. It moves our company forward as customers look for unique ways to work while contributing to sustainability goals set by their employers.”

Ultimate Service Body Protection

Auto Crane also offers Titan Armor®, an industrial paint coating system used in the marine industry to protect ships at sea and adapted it for truck bodies. Titan Armor protects ten times longer than industry standard paints in salt spray testing. “It extends corrosion protection from the typical 500-hour salt spray performance of automotive paints to over 5,000 hours,” Hausman says. “That helps solve the problem created with current de-icing chemicals being used on roadways. It’s unique. There’s no one else with anything like this in the market.” Especially designed for highway, coastal marine and offshore applications, Titan Armor keeps rust from spreading where paint is chipped and scratched and provides overall corrosion protection from undercoat to topcoat. “When you scratch paint and expose it to the elements, it will bubble up and the elements will eat it,” Hausman says. “Titan Armor won’t let it creep further. That’s why it’s a big deal.” Titan Armor is enhanced for exterior surfaces to fill gaps and protects areas its competitors leave behind. It has double impact resistance of automotive/fleet paints and improved adhesion for better performance.

Let one of our trained salespeople or certified dealers show you why Auto Crane is the leader in innovation, safety & reliability.