The following considerations should be made when installing an EH crane:

- Chassis alternator rating

- Adding an auxiliary battery to boost power

- Auxiliary battery isolation

- Wire type and size

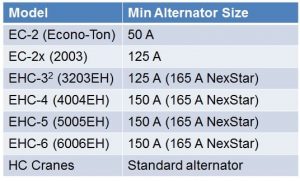

Chassis Alternator

The chassis alternator should have a minimum size as follows:

The smallest alternator available on a 2020 Ford F-250/350/450/550 is sufficient with 157 A. If the alternator is not sufficiently rated, an auxiliary battery can be installed.

Auxiliary Battery

Adding an auxiliary battery allows for a smaller alternator as well as makes it possible to turn-off the chassis while running the crane for a short amount of time. The type and isolation need to be considered.

The auxiliary power connection must be fused like the chassis battery. See the Crane Power Protection bulletin for further details.

NOTE: the auxiliary battery that is connected to the Voltage Switching Unit (VSU) on an EHC-5 or 6 cannot be used to power accessories since the VSU switches the connection to make 24V while operating the crane. Reference the VSU bulletin for more information and troubleshooting.

Type

A flooded standard or deep cycle battery should be used. A BCI Group Size 31 battery is recommended like the Interstate Batteries P/N SRM-31. Maintenance free batteries such as sealed, VRLA, AGM and GEL are not recommended.

Isolation

Adding a switch or isolator such as the InPower ABS-200 (Auto Crane PN 305605000) module prevents the chassis battery from being discharged to the point the engine cannot be started. It also allows the chassis battery to supplement the ampacity to help keep the crane operating at top speed with full rating especially when the engine is not running.

The ABS-200 module allows the wire size for connecting to the chassis battery to be reduced to 2 ga with a 225 A fuse instead of running 00 ga with a 300 A fuse. The manual for the ABS-200 is linked below.

Wire

Type

Use a cross-linked insulation such as SGX is best suited for battery power connection. The 125°C rating handles the temperatures often reached under the hood. Smaller (10 ga) wires should have GXL, SXL or TXL type insulation.

Using PVC (GPT, TWP or HDT) type insulation is not sufficient since this insulation is typically rated to 175°F (80°C).

Size

The table below shows the recommended wire size for temperatures under the hood which can reach 255°F (125°C). For instance, a size 00 wire should be used to supply 300 A. If the ABS-200 isolator is used the wire size can be reduced to 2 ga since the module limits the current to 200 A.

Last Update: November 25, 2020

Tell us how can we improve this post.

Log In is required for submitting new question.